Disposal Treatment Equipment For Oily Drilling Waste With Microwave

A large amount of oil-bearing cuttings are produced during oil extraction, which contains a large amount of mineral oil, phenolic compounds, heavy metals and other toxic substances and these substances will cause serious damage to the ecological environment. Among them, oil is the most important environmental pollutant. On May 1, 2009, China promulgated the “Emission Limit for Exploration and Development of Offshore Oil”, which clearly stipulated that the oil content of emissions should be less than 1%. The effective treatment of the oil content in drill cuttings is directly related to the safety discharge problem. At the same time, it also involves a lot of resource recycling problems.

Using high-power microwave rotary kiln to harmlessly treat with oil-based drilling cuttings can effectively separate oil and water, drill cuttings and other substances. This realize the recovery and reuse of oil water resources, and promote the harmless treatment technology of wastes, meanwhile, it can also greatly shorten the processing time, reduce processing energy consumption, and provide power for the creation of energy-saving, environmental protection, and environment-friendly society.

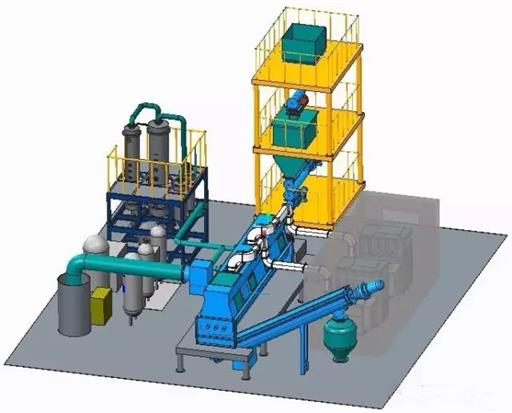

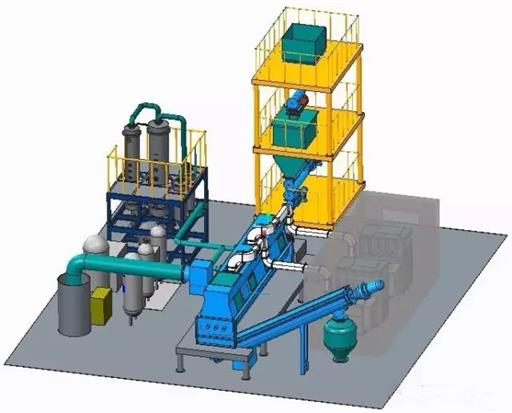

The equipment line uses microwave energy to heat the oil dust in an oxygen-separated environment, so that the oil content in the oil chips continuously evaporates, and ultimately it is less than 1%, reaching the national emission standards.

Features:

♦Non-contact direct heating to materials by using microwaves is efficient and fast.

♦It can quickly and evenly handle oily cuttings, reducing the oil content to less than 1%, and at the same time, recycling;

♦The base oil produced during the treatment increases the economic efficiency of the treatment.

♦The entire process has achieved a high degree of automation, controllability, and greatly saved labor costs.

♦Compared with traditional treatment methods, its process flow is simpler and easier to operate; and there is no waste gas and waste water are produced in production process and it has achieved safe and environment friendly.

♦The equipment takes small space and easy to produce in batch processing.

Related Items