Biomass Pyrolysis Plant for bamboo or wood with microwave technology

This project has been suspended.

This project has been suspended.

This project has been suspended.

Our biomass pyrolysis plant with newly microwave technology can get products:biomass charcoal or called biochar,biomass tar,biomass vinegar(such as wood vinegar,bamboo vinegar),biomass gas( syngas )which can be used as the preheating for the raw material or as a syngas source for syngas electrical generator.

For example ,if the raw material is bamboo,you can get bamboo charcoal(At present the bamboo charcoal is mainly used in air purification, healthcare, fuel, food and water quality and other aspects),bamboo oil,bamboo vinegar,and bamboo gas.

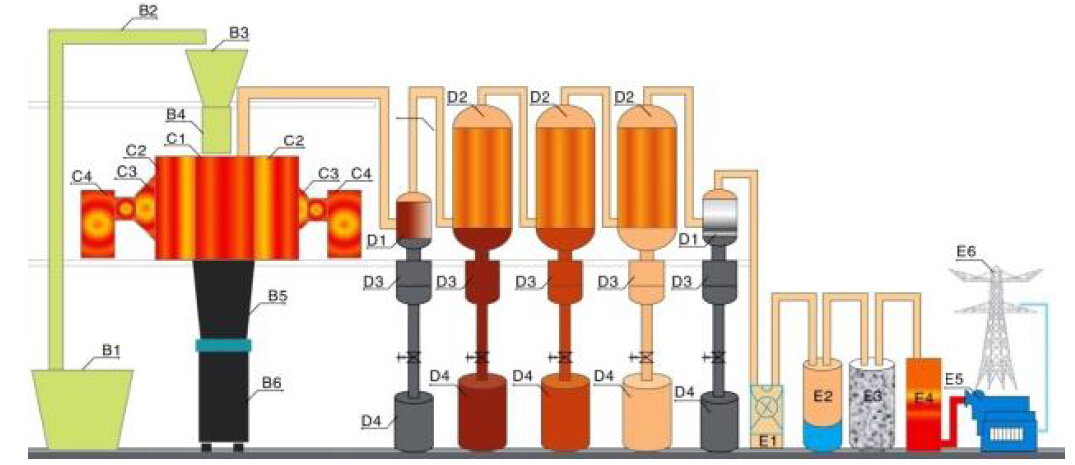

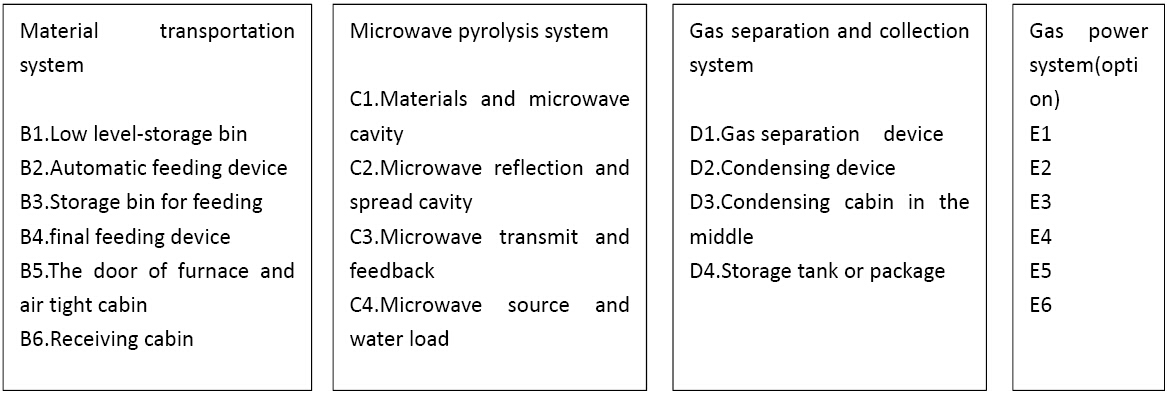

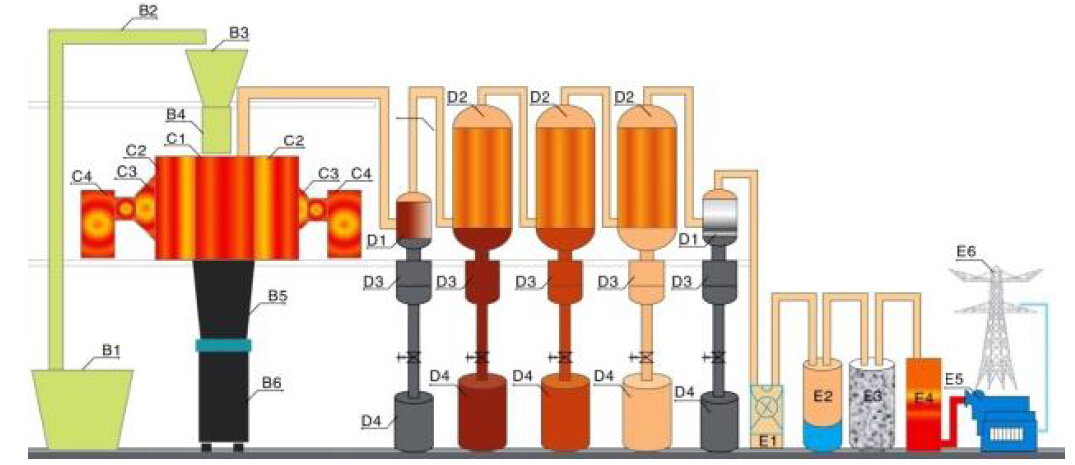

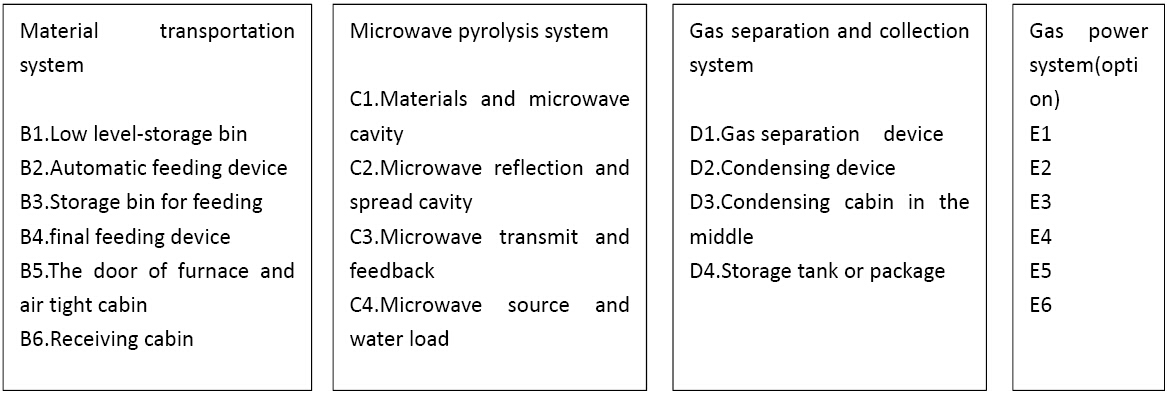

Flow Diagram for Biomass Microwave Pyrolysis Equipment

System composition of Biomass Pyrolysis Equipment:

This system is composed of raw material transport system,biomass microwave chambers heated by 6 sets of75KW microwave generator whose microwave power is 75KW and the total power is 450KW,biomass oil & liquid & gas separation and collecting system.

Features :

1.Large Production

Compared to traditional method of producing bamboo-charcoal, microwave production method has the characteristic of large production.

Traditional kiln only produces over 300 KGS bamboo-charcoal per time, however, microwave oven can reach 1.77 tons of preheated material, 100 minute for one pithch(The time can be adjusted by different requirement).

2. Efficiency can be increased more than 70%

In order to heat object, microwave penetrates it from all directions and this process does not require thermal conduction. With the features of rapid and uniform heating and temperature gradient control, microwave heating could effectively reduce heating time, so its thermal efficiency is very high and compared with common heating its efficiency can be increased more than 70%.

3. Suitable for large-scale industrial production

Compared with traditional way of making charcoal which needs more than 24 hours, the microwave carbonization time that needs only 100 minutes,which is sharply reduced. So the latter will be more suitable for the need of large-scale industrial production.

4. Products are easy to collect

biomass Charcoal, vinegar, bamboo tar and combustible gas generated in the process are easy to collect.

5.Can achieve automated continuous production

Producing charcoal by microwave can reduce labor intensity and production personnel and also achieve automated continuous production.

6.Reduce the demand of fuel,save enery

In addition, charcoal preparation by microwave could reduce the demand of fuel such as wood which are much consumed in traditional kiln preparation. This will help save forest resources and protect ecological environment.

7.It is favorable to economic cycle.

The basic parameters:

Input power: three-phase 380V±5% 50Hz±1%

Ambient temperature: 0—35 ℃

Relative humidity: ≤85%

Work area: no inflammable, explosive or corrosive gases.

Microwave power: 450KW(there are other types :900KW,1800KW,2760KW)

Microwave frequency:915MHz±10MHz

Processing capacity: 1.67tons per furnace, 100minutes/ furnace

Cooling system: water cooling + air cooling

Microwave leakage: ≤1mW/CM2

Related Items